Contact Us

Nanjing Jim Sensing Technology Co. Ltd.

Contacts:Manager Zhu

Tel:025-86200765

E-mail:leo@jmtsensor.com

Online QQ:3895478

Address: Nanjing wiscom Park 8 Building

Method for selecting displacement sensor

Method for selecting displacement sensor

Displacement sensor is a system device. As a measuring device, it plays a key role in many applications. Displacement sensors are used to measure mechanical displacement of the instrument, as well as the amount of displacement of the machine during industrial processing. The displacement sensor has higher precision requirements in the detection, such as the constant requirement of the ambient temperature, the precise control requirements of the movement mechanism, etc..

For the selection of displacement sensors, buyers need to understand the working principle of the displacement sensor and installation method. Displacement sensors, like other sensors, convert the amount of change seen in reality to electrical signals. According to the general displacement size and the needs of users to choose what sensor precision, need to consider the error sensor and its good range of application environment of corresponding users on whether data acquisition influence etc.. The displacement sensor is also a sensitive device. When you buy it, you should know the relevant points for use, so that the sensor can last longer.

1. Determine the type of sensor in accordance with the measurement object and the measurement environment

To carry out a specific measurement work, we must first consider the principle of the sensors used, which need to analyze a variety of factors before they can be determined. According to the characteristics and conditions for the use of the measuring sensor is considered following some specific problems: the range of the size of the measured position of the sensor; volume measurement; contact or non-contact; extraction method of signal cable, or non contact measurement; source of the sensor, domestic or imported, the price can bear still, developed. After considering the above issues, you can determine what type of sensor to choose, and then consider the specific performance indicators of the sensor.

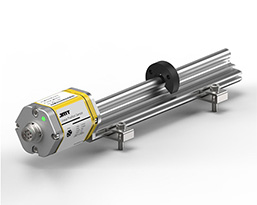

Displacement sensor

2, sensitivity choice

Usually, in the linear range of the displacement sensor, the sensitivity of the sensor is expected to be higher. Because only the sensitivity is high, the value of the output signal corresponding to the measured change is relatively large, which is beneficial to signal processing. However, it should be noted that the sensitivity of the sensor is high, and it is easy to be mixed with the external noise which is not measured. It also amplifies the system and affects the measurement accuracy. Therefore, the sensor itself should have a high signal-to-noise ratio, so as to minimize the interference signal from the outside. The sensitivity of the sensor is directional. When the measurement is unidirectional and requires higher directivity, sensors with small sensitivity in other directions should be selected. If the measurement is multidimensional vectors, the smaller the cross sensitivity of the sensor, the better.

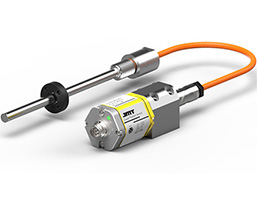

Displacement sensor

3, linear range

The linear range of the displacement sensor refers to the range in which the output is proportional to the input. In theory, sensitivity is maintained within this range. The wider the linear range of the sensor is, the greater the measurement range and the accuracy of the measurement. When choosing a sensor, when the type of sensor is determined, it is necessary to see whether the measurement range meets the requirements. But in fact, any sensor does not guarantee absolute linearity, and its linearity is relative. When the required measurement accuracy is relatively low, within a certain range, the sensor with smaller nonlinear error can be approximately regarded as linear, which will bring great convenience to measurement.

Displacement sensor

4, frequency response characteristics

Displacement sensor frequency response characteristics determine the frequency range to be measured in the frequency range, must be allowed to keep the measurement conditions without distortion, in fact the total response of sensor - delay, delay time as short as possible hope. The frequency response of the sensor is high, the measurable signal frequency range is wide, and because of the influence of the structural characteristics, the inertia of the mechanical system is larger, because of the low frequency of the sensor, the frequency of the measurable signal is lower. In dynamic measurement, response characteristics should be based on the characteristics of the signal (steady state, transient, random, etc.) so as to avoid excessive errors.

Displacement sensor

5, accuracy

Accuracy is an important performance index of sensors, and it is an important link to the measurement accuracy of the whole measurement system. The precision of the sensor is high, its price is more expensive, therefore, the precision of the sensor as long as meet the measurement accuracy requirements can be, does not need to be so high. This makes it possible to select cheaper and simpler sensors in many sensors that meet the same measurement purpose.

If the measurement objective is the qualitative analysis, the sensor can repeat precision, should not use the absolute value of high precision; if it is for the quantitative analysis, to obtain accurate measurements, it will have to choose precision can meet the requirements for the sensor.

Displacement sensor

6, stability

The ability of a sensor to remain unchanged for a period of time is known as stability. In addition to the sensor itself, the main factors affecting the long-term stability of the sensor are the sensor's use environment. Therefore, in order to make the sensor have good stability, the sensor must have strong adaptability to the environment. Before selecting a sensor, it should investigate its use environment, select the appropriate sensors according to the specific environment, or take appropriate measures to reduce the impact of the environment. The stability of the sensor has a quantitative index, in excess of the use period, before use, should be re calibrated to determine whether the performance of the sensor changes. In some situations where sensors are required for long periods of time and cannot be easily replaced or calibrated

Key word:Method,for,selecting,displacem