Contact Us

Nanjing Jim Sensing Technology Co. Ltd.

Contacts:Manager Zhu

Tel:025-86200765

E-mail:leo@jmtsensor.com

Online QQ:3895478

Address: Nanjing wiscom Park 8 Building

Wiring method and installation of displacement sensor

Wiring method and installation notice of displacement sensor

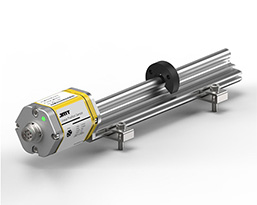

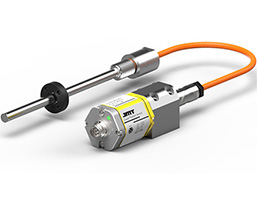

Displacement sensor, also called linear sensor, is a linear device with metal induction. The function of sensor is to convert various measured physical quantities into electrical quantities. In the process of production, displacement measurement is generally divided into two kinds: measurement of physical size and mechanical displacement.

Displacement sensor before installation, users do not disassemble, modification (including tear to the trademark, processing, in the shaft and the casing on the loose nails, locking ring Piao rotation position). In the installation process, the displacement sensor should be handled with care so as not to touch the lead out;

1, the displacement sensor mounting lug positioning, with screws, nuts or pressure plate firmly attached to the metal plate. When a sensor is installed on the shaft and housing, prohibited vehicles, drilling and other processing, avoid the shaft or housing by external impact force and pressure, axial and radial not permitted by the impact and pressure (static pressure should be less than 300N). Do not loosen the screws on the sensor and turn the fastening ring in place.

2, displacement sensor shaft and other parts connection should pay attention to the axis line to keep it in a straight line (including working state), such as axis deviation, recommend the use of universal joint or corrugated pipe connector, so as to avoid the sensor shaft bending deformation, damage to other devices, thus affecting the use of.

3, should prevent water droplets, vapors, solvents and corrosive gases on the displacement sensor attack, prevent metal debris or other powder into the sensor.

4. The external wiring of the displacement sensor shall be welded at the lumbar slot at the lead out side and try not to solder it at the top of the extraction terminal. Welding shall be used not less than 45W ferrochrome, welding time shall be less than 5 seconds. The wires should not be pulled in or out of the weld so that the brush wire or the entire extraction end is pulled out or even removed.

Key word:Wiring,method,and,installation